Wasserschmidt introduces new sludge-separation system at Autotechnica

The German company Wasserschmidt will introduce a new sludge-separation system for tunnel car washes at the Autotechnica trade fair in Brussels. “Because car washes are getting bigger and bigger, you really need to think about how to properly seperate and store all that sludge.”

Clean water is the most important part of any car wash. In order to keep this water usable in the recycling process, you need to filter and separate the sludge from it. But with the upscaling of tunnel car washes with up to 50.000 liter of wastewater per hour, you need to dig deeper and deeper in order to be able to store all the wastewater.

“Every car that is being washed leaves 300 to 400 grams of sludge”, according to Jakob van Nimwegen of Wasserschmidt in Legau. “Where will you store all that wastewater? You will need enormous wells for it. When you upscale, it eventually becomes too expensive. You really need to think about how to properly seperate and store all that sludge.”

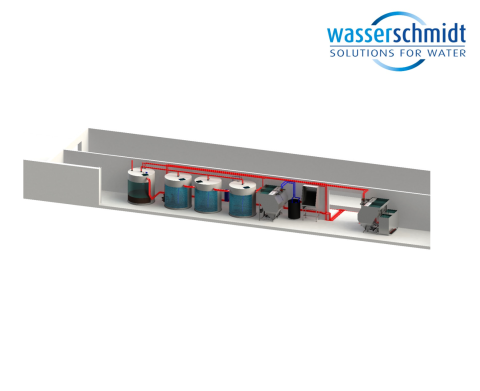

Wasserschmidt comes with the perfect solution. Their BioClassic System is a must for any newly built tunnel car wash with large volumes of wastewater. The sludge separation is intended to complement Wasserschmidt’s BioClassic water purification system.

Contaminate

“In standard water recycling systems, the sludge is stored in huge collection wells. You need to empty them when they’re at 50% capacity, which is often forgotten”, knows Van Nimwegen. “The problem with sludge is that it consists not only of sand but also of organic material that looks like oil. This organic material can suddenly contaminate the entire water treatment plant with all its consequences.”

With the new filter system from Wasserschmidt, significantly fewer sludge collection pits are needed. This saves on the investment that must be made in the construction of concrete pits and the associated earthwork.

Keep things running

Another great advantage is: the tunnel wash does not need to be closed. Washing can continue as usual. This prevents loss of turnover during the emptying of sludge collection pits.

The system is already operational in countries like Germany, Belgium and Norway, where they have a huge petrochemical industry present. Furthermore, legislation on groundwater quality is very strict in Scandinavia.

Costs

Van Nimwegen hesitates when asked how much the system costs. “It really depends on the scale of the project”, he says. “We recently installed one in Oslo, where it was difficult to install wells in the ground.”

Once installed, Wasserschmidt gives a lifetime guarantee on their Bio Filter System. “We really believe in this technique.”

The new sludge-separation system can be seen at Wasserschmidt’s booth (Stand 502) in Hall 5 of the Brussels Expo. Autotechnica & Service Station will last from Sunday, March 27 through March 30, 2022.

Also read: