Caramba!! Save water with X-Jet nozzles

The new X-Jet water-saving nozzles by Caramba could save up to 30 percent in water usage during a car wash, according to the German manufacturer. Compared to an ordinary cleaning the results would be similar. In an industry where sustainability is the driving topic, this innovation might well be the golden nugget.

The German company Caramba recently presented their new X-Jet water-saving nozzles to the world. They incorporate exclusive and patented nozzle technology based on an oscillating droplet jet.

Rotating drops

This new technology puts the spotlight on a technical area in car washes that has received little attention until now. Conventional flat spray nozzles produce a spray fan that sags at the sides and tends to form uneven droplets at the edges. As a result, the water and chemical application can neither cover the entire area nor be uniform over an entire surface, Caramba argues.

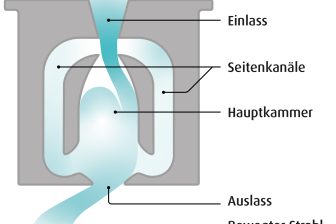

The new X-Jet nozzles use a different technology. The water jet is directed inside the nozzle through a main chamber and two side channels, which influences the outlet of the water jet. The result is thus not small, sprayed water drops, but larger drops that also rotate.

This rotation results in a more uniform droplet pattern and the rotating drops penetrate the water film on the surface more easily. This speeds up the time it takes for the water film to break up and increases the efficiency of the washing chemicals used and the drying process.

Less water consumption

The new technology uses up to 30 percent less fresh water per wash. A calculated example shows the financial impact: Compared to conventional flat-jet nozzles, the X-Jet nozzles use 16.5 liters less industrial and fresh water. In return, the X-Jet nozzles are used in the low-pressure range below 20 bar in the clear rinse, dryer sheet, wax sheet and osmosis rinse.

With around 100,000 washes and an average water price for fresh and waste water of €5.50/m³, this results in savings of around €9,000. This means 1.65 million liters of water less per year. Caramba illustrates this saving with the comparison that around 36 single households could cover their annual freshwater consumption with this amount of water.

Switching is easy

The uniform droplet jet means that water application is no longer dependent on constant water pressure. With conventional flat-jet nozzles, this breaks down when the water pressure drops. The new X-Jet nozzles are also less susceptible to wear due to their different technology, as no sharp edges have been processed and no moving parts have been used.

Switching from flat spray nozzles to the new X-Jet nozzles is very easy, Caramba states. The X-Jet nozzles can be used in any car wash, because the conversion is done by simply replacing the nozzles.

The X-Jet nozzles are available in a variety of sizes and angle designs. “The X-Jet nozzle range fits perfectly with Caramba’s holistic process approach. Here, the company combines its development expertise in specialty chemicals with targeted process know-how,” explains Patrick Maione, Key Account Manager National at Caramba.

Also read: