Which sustainable innovation will win an award at the CWSE?

In the sustainability category, products by Dr.Stöcker, INOWA and GDP Biotech are the three finalists for the Car Wash Innovation of the Year Award. If you want to know who wins, come and visit the Car Wash Show Europe.

Innovations within the other categories have already appeared online: technology and digitalization. But which innovations are competing in the sustainability category? CarwashPro gives the answer.

Bag-in-Box: 90 percent less plastic

Sustainability is a relevant topic in the car wash industry. Since the introduction of more sustainable packaging and the improvement of the biodegradability of many soaps and waxes, Dr. Stöcker has worked continuously to improve the ecological balance of its products.

In Germany and other countries, car wash chemicals are sold in 25-liter jerry cans, separate from drums and IBCs. One such can consists of about 1,000 grams of plastic. To reduce this large amount of plastic, Dr. Stöcker presents a more sustainable alternative: the Bag-in-Box.

More space in the car wash

The Bag-in-Box is a cardboard box containing a 20-liter foil bag. “Compared to the can, this bag consists of only 100 grams of plastic – or about 90 percent less plastic,” Dr.Stöcker explains. “Compared to a can, this not only reduces CO2 emissions during plastic production, but also during transport of the cans, which weigh about 900 grams.

Moreover, a carwash produces about 90 percent less plastic waste in the form of empty containers, which have to be collected by waste management companies every month.

With the Bag-in-Box, collection of the empty 100-gram flat foil bags is reduced to about one or two truck trips per year for the same amount of chemicals. This eliminates the storage of the many bulky empty jerry cans and creates a lot of space in the car wash.”

(Text continues below image)

With the specially developed wall dispensing system, the Bag-in-Box boxes remain suspended on the wall.

On the wall

Without the Bag-in-Box system, the jerry cans are often placed on the floor in the equipment room under the dosing pumps. “When the jerry cans are replaced, the hoses have to be pulled out of the jerry cans, so chemical dust usually ends up on the floor or in the collection containers,” says Dr.Stöcker. “In addition, when changing the cans, there is always the risk of carwash employees coming into contact with the leaking chemicals.”

With the specially developed wall dispensing system, the Bag-in-Box boxes remain suspended on the wall in a stainless steel wall holder. The side-mounted riser tubes are transparent and visually indicate the fill level. Below the riser tube is a 500-mL reserve tank with measuring scale, whose contents are sufficient for up to 50 washes, depending on the type of wash.

“Another important advantage for the carwash operator is that with the Bag-in-Box he or she can communicate to his customers that the carwash is sustainable. This is an important argument for many carwash customers whether or not to wash their car at a carwash,” said Dr.Stöcker.

Want to know more about the Bag-in-Box? Dr. Stöcker will be present at Car Wash Show Europe with a booth: booth number 1.03.01.

Fixed-bed bioreactor: new standard in water treatment

INOWA specializes in solutions for wash water technology and presents the fixed-bed bioreactor: “Treating and reusing wash water is basically nothing new and there are many suppliers on the market. But new developments in wash technology, such as Express Wash or powerfoam, have a significant impact on the design of the water treatment system. Filtration systems alone are often no longer sufficient to achieve optimal washing results.”

“However, the development of our fixed-bed bioreactor sets new standards in the field of wash water treatment,” said INOWA. The remaining wash water is fully biologically processed in the bioreactor and returned to the wash system until it is crystal clear and odor-free. This means that up to 95 percent of fresh water in car washes and car wash facilities can be replaced with fully biologically treated water. “Sustainable and in a way that conserves resources.”

text continues under photo

An added benefit: by monitoring oxygen levels, the aerators’ run time can be adjusted according to need, keeping electricity costs to an absolute minimum.

The fixed-bed bioreactor can be used not only in portal car washes and car washes, but also in self-service car washes. “Here, too, up to 85 percent of the fresh water can be replaced with fully biologically treated water. This means that the carwash can continue to run even in times of water shortage.”

BIO certificate

To make carwash customers more aware of sustainable water use as a resource, carwashes using the system are awarded a BIO certificate. “Commercial carwashes do not pollute the environment or waste resources, quite the contrary. We have to include the end customer in that as well.”

Wondering how it it works? Watch the video here.

Want to know more? Then click here.

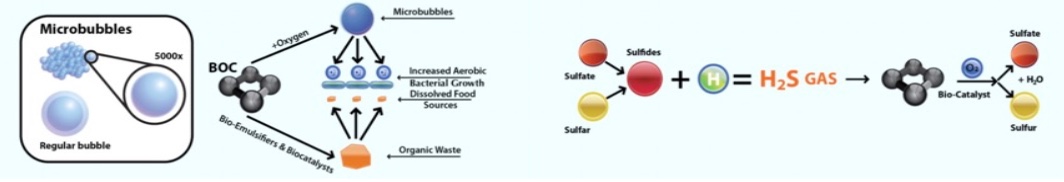

Bio-Organic Catalyst’s (BOC): revolution to detergent-free washing

“BOC offers a patented technological nanofluid that is groundbreaking within the industry of traditional water treatment and detergents” says GDP Biotech, the company behind this innovation. “It is made from 90 percent yeast and the rest is surfactants from Mother Nature. So it is 100 percent sustainable and not a chemical or a product based on bacteria or enzymes.”

GDP Biotech continues: “One product can replace all the chemicals, detergents and biocides used in the car wash. This creates a complete car wash without detergent, which in turn benefits the challenges currently facing the European carwash industry.”

“In terms of environmental regulations, the discharge water when using BOC is of high quality. There is more than 80 percent water recovery in water recycling which is a significant water saving.”

(Text continues below image)

BOC offers a patented technological nanofluid.

Cost reduction

In addition, BOC contributes to operational cost reduction, the company says. For example, it replaces multiple products for one. Does it reduce water bills. Is there lower energy consumption because it works with cold water. It also extends the life of the appliances by removing the biofilm layer, preventing rust and congestion. And which optimizes performance.

“With customers’ preferences moving toward environmental friendliness, a car wash meets this requirement thanks to the use of BOC. It also leaves no streaks on the glass, provides a better shine and removes all bacteria and viruses by removing the biofilm layer. “In addition, BOC is completely safe for the employee because there is no chemical impact on the body, which also eliminates the need for gloves.”

‘Revolutionary change’

“European carwashes are navigating a complex landscape of environmental regulations, sustainability requirements, technology and customer preferences, while having to consider competitiveness and financial viability. BOC offers a complete cycle of 360-degree sustainable innovation for revolutionary change.”

Please cast your vote

Want to vote for your favorite sustainable innovation? Cast your vote here. Voting is also already open within the digitalization and technology categories.

During the fair on September 21, all innovations will be presented in our innovation gallery. You as a visitor decide who wins. For each category you can vote for your favorite. Will you be there to support your innovation? Register here for free for Car Wash Show Europe!

Also read: