Meet Rick, a Dutch car wash veteran

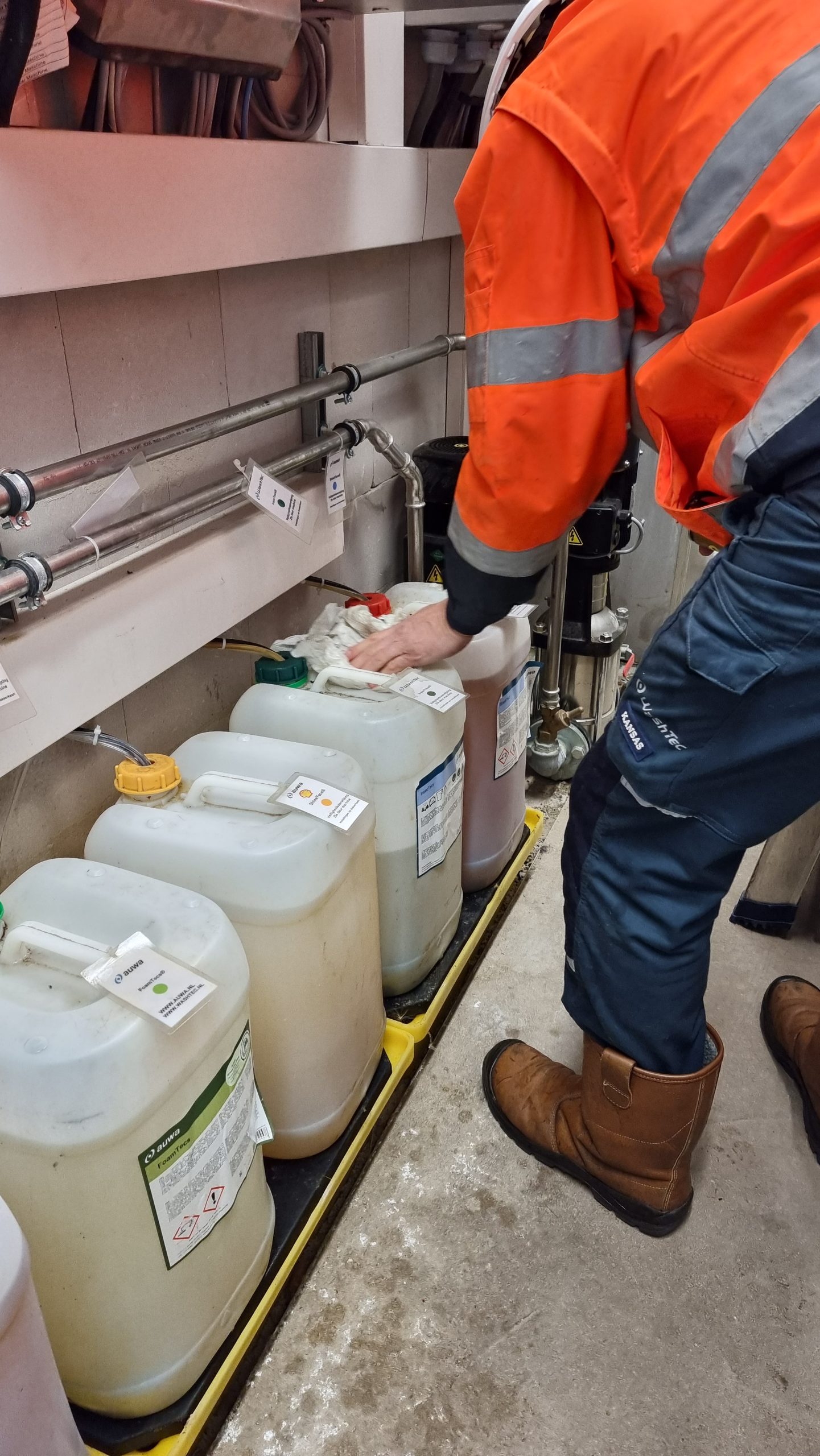

Dutch car wash veteran Rick Nieuwenhuijs has installed car washes for decades and did service maintenance for all of WashTec’s car washes in The Netherlands. Nowadays, he is on the road as a ‘carwash troubleshooter’, solving all kinds of problems be it technical or chemical. “This is something I can continue for years to come.”

Dutch car wash veteran Rick Nieuwenhuijs has been with WashTec and its predesessors since April 1984 and has many years of experience in the carwash business Photos: WashTec

Rick has been with WashTec – then called Kleindienst in The Netherlands – since April 1984 and has been through all the mergers. His career began with production work in the workshop. Then he started working as a service technician, driving his van all over the country. “I specialized in WashTec’s JetWash, I really knew everything about that,” he said.

Currently, Rick has been working as a chemistry specialist for two years. When the AUWA chemistry and the machine need to be adjusted to each other or when there are problems with them, he comes by to fix it.

(Text continues below photo)

Rick still drives his bus all over the country.

Variety

Although chemistry requires a different way of working, it is a welcome change for Rick. “Especially considering my age. The work is less physically demanding, but certainly no less challenging. It’s just that the problems you are facing are very different. These problems never have to do with chemistry. That’s just top notch. It has been tested plenty. This means you often have to dig a bit deeper. Is it the aeration? Is it the calibration or is it the machine itself? This kind of stuff makes my workdays exciting and challenging.”

Thanks to his technical background, Rick always finds a solution. “Often it comes down to something technical, and then it’s an advantage that I know how to adjust the machines. This often helps determine the problem to see what’s going on.”

He also likes the trends in chemistry. “Sustainable products, which are friendly to people and the environment, have become much more important in recent years. AUWA has the ‘Green Car Care’ label on its entire product range, which is unique in the industry. And that plays a big role with more and more entrepreneurs.”

(Text continues below photo)

Development

The mechanics profession is evolving with technology over the years, Rick observes. And that’s mainly in terms of the rapidly changing machinery. “You used to have to actually tinker with them and now it’s mostly software. That’s a big difference. Also to the customer. A machine used to consist mainly of hardware and nowadays they are more ‘smart’ because of all the new possibilities and digital solutions. Also, we are now able to significantly improve the washing result with more options. An average rollover used to have four chemicals and today seven is no longer exceptional.”

For years to come

Rick would love nothing more than to continue with this work for years to come. “I think I am one of the few chemistry specialists, with over thirty years of technical background, who has experienced so much of the carwash industry. Even with California’s first rollovers back in the day. I still enjoy helping customers and engineering installations, which comes together perfectly in my current role as a chemistry specialist.”

Also read: