Pitlane: The longest conveyor car wash of Scandinavia

With a double conveyor belt of 45 meters, the recently opened Pitlane Bilvask in Norway has the longest car wash in Scandinavia. We spoke with proud manager Thomas Hovda about the challenges of washing cars in the often harsh winter conditions in Norway.

In a way, Pitlane Bilvask is the ultimate revenge. For years, Thomas Hovda was running a franchise car wash in Gjøvik (just north of capital Oslo) for Circle K.

When that multinational decided not to continue the franchise because they wanted to operate the wash themselves, Hovda took a leap forward. He decided to make his dream come true and opened a huge car wash complex, right across the street of his former employer.

“I had been running the old rollover for many years in Gjøvik, so I knew there were enough customers passing through the town that would justify a bigger wash”, Hovda explains.

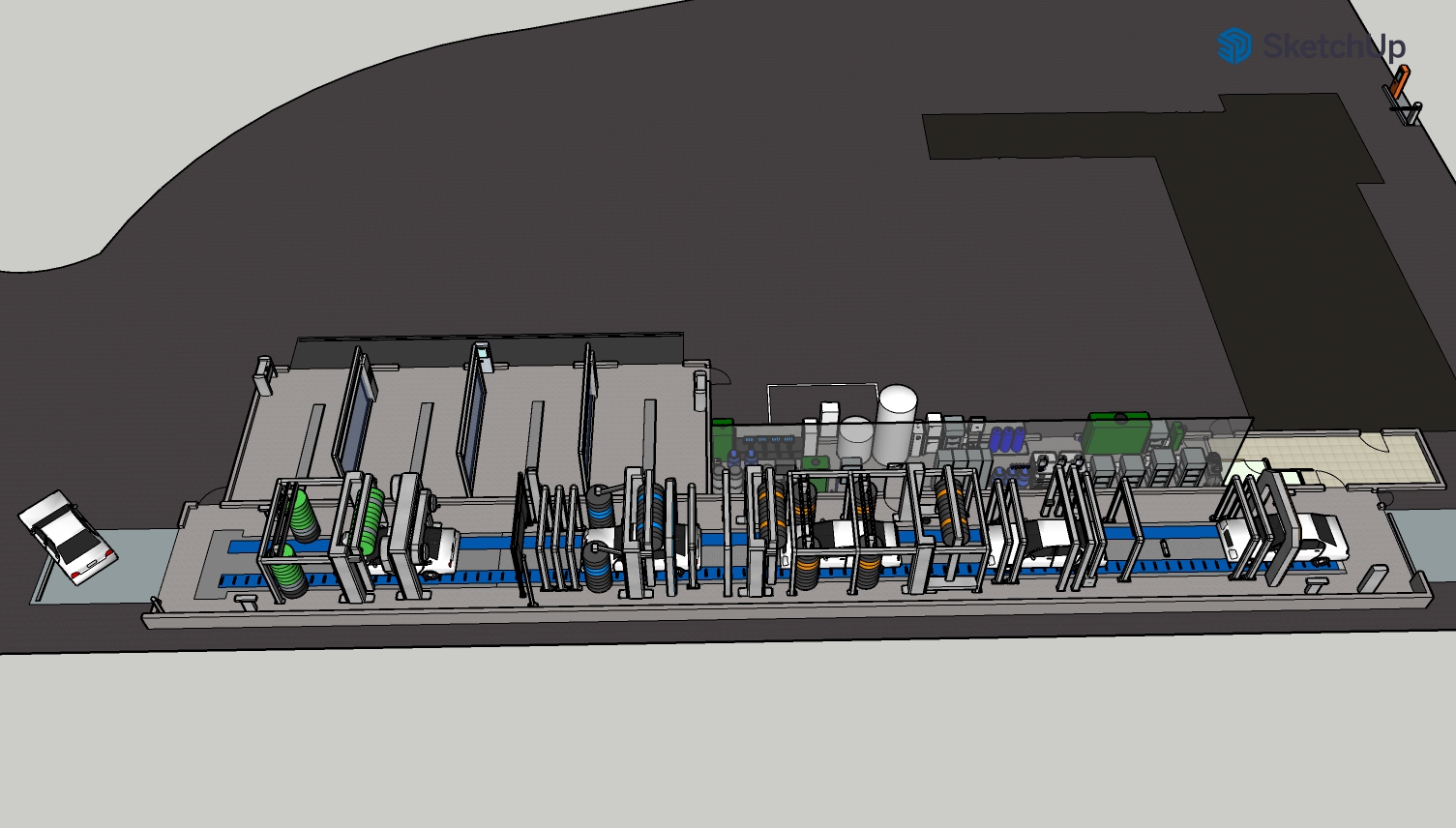

And bigger is no exaggeration. The newly opened Pitlane car wash offers a 50 m long tunnel wash and four covered and heated wash bays. In the near future, Hovda wants to expand the business with a charging station for EV’s, a convenience store with fast food and even a diner with seating.

The Norwegian media calls Pitlane the longest car wash in Norway or even Scandinavia. Is tunnel washing so rare in the northern countries?

“Tunnel wash is not so common in Norway yet, it is mainly roll-overs at petrol stations from established big chains that own the market. But that is changing now. More and more independent sites are established, still mainly roll-overs. Our tunnel is 50m, which is not the longest over here. But the conveyor is 45m and that makes it the longest conveyor in Scandinavia.”

It can be pretty cold in Norway in winter. What makes car washing in your country different compared to other countries?

“It is a fully automatic car wash with lots of equipment. The machines are from Istobal, more precisely, we picked their T’WASH30 model. It is the most heavily equipped machine Istobal has ever delivered, they said to me.”

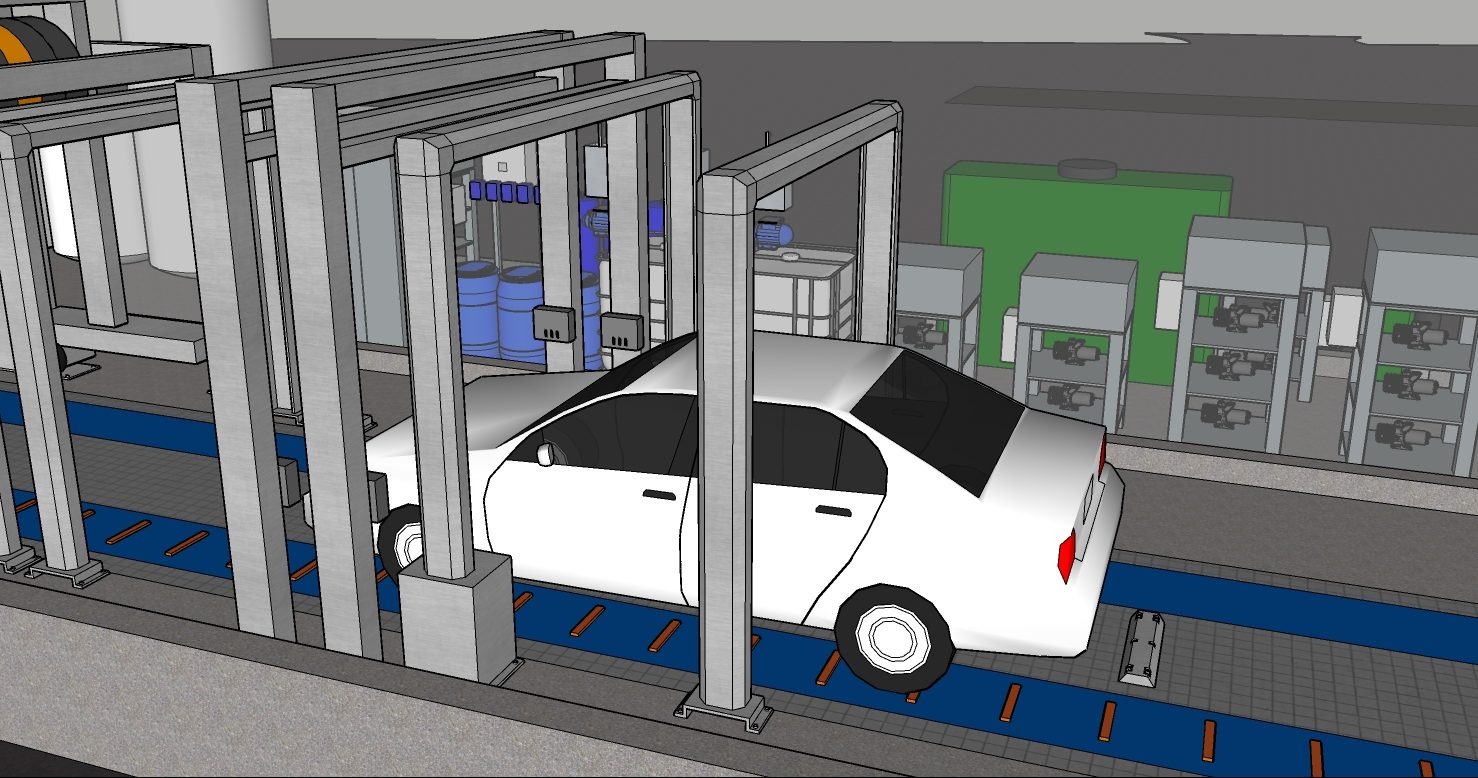

“Furthermore, It is the first machine they deliver in cooperation with a conveyor belt from STI Conveyor Systems in Canada. It was very important for me to have a double belt system and not the old single chain solution. I am convinced this will take over the market in the next few years.”

Small staff

Hovda tells us that in Norway the labor cost is so high, it’s hard to run the car wash with a lot of staff. You need to find smart solutions for this. “The Istobal machine and the conveyor can be operated by a single employee and their main task is to talk and guide the customers at the entrance to the pit.”

Another challenge with a small staff is the pre-wash. Which needs to be done properly because of the harsh winter conditions in Norway. “We can not offer manual pre-washing with high pressure and things like that. Instead, all the pre-wash will be done by machines. With this we have to take in mind the heavy winter conditions in Norway.

“Often, cars come in covered in salt and dirt, so we had to customize the pre-wash to our harsh climate. You need strong detergents over here and a lot of high pressure to get the dirt off beforehand, in order to prevent unnecessary wear and tear to the paint.

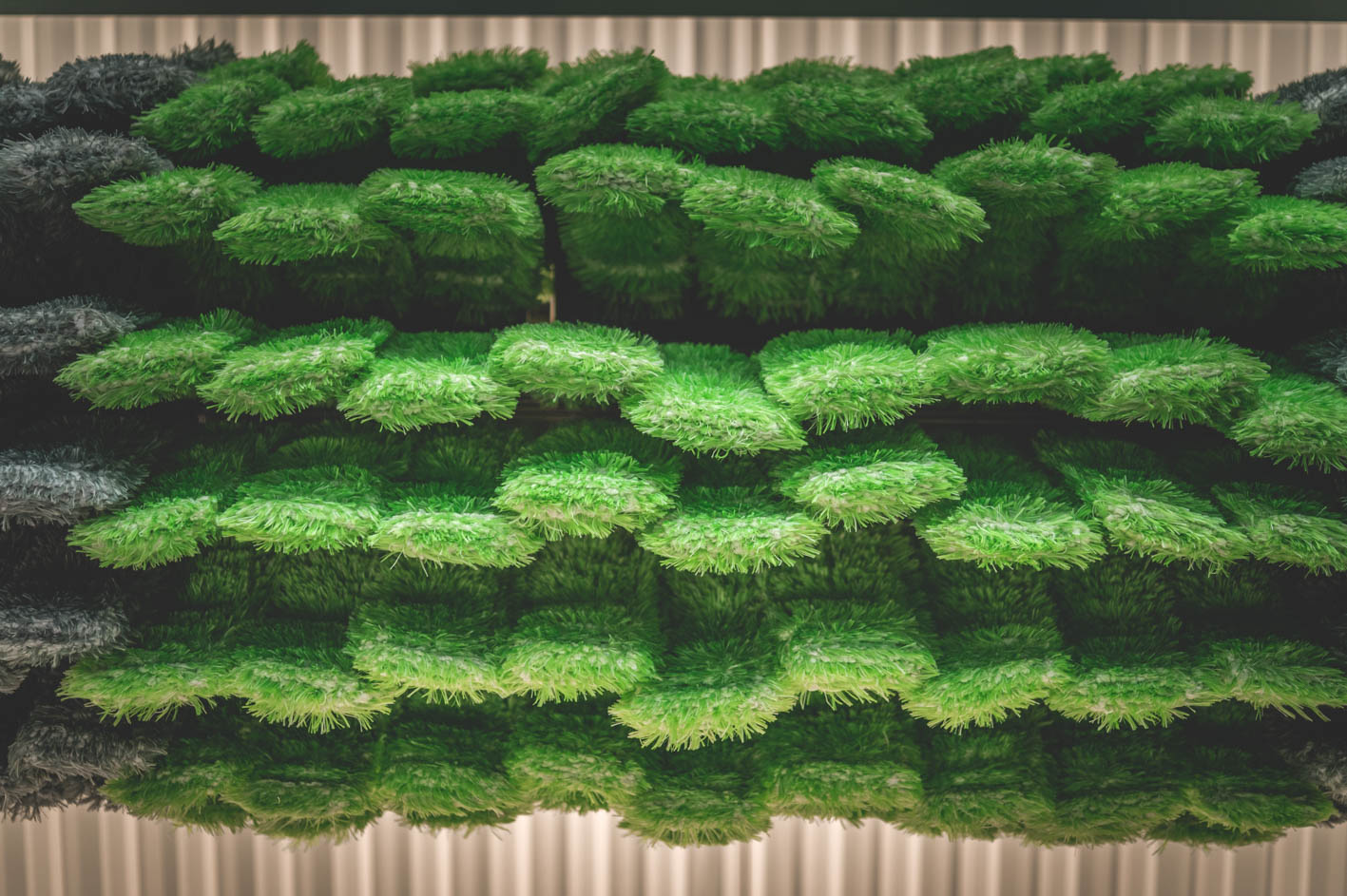

“Therefore, we have a specially designed high pressure for the front and back which is mounted in the floor. Together with double bays with high pressure all over the car. The next section is the washing with brushes: 4 side brushes and 2 roof brushes. Then a separate polish section with roof and side brushes, a 3 stage rinse and dry blower. For the last phase we wanted drying brushes. They have microfiber clothing by Aqua Brush. These soft brushes make the cars shine.”

Norway has a large amount of EV’s. Does that put your wash to extra challenges?

“It does. Over 80% of the cars sold in Norway are indeed now electric. The challenge with all the different brands is how to get and keep them neutral, while in the car wash. There are so many safety solutions to prevent the car from rolling unintended. We are actually compiling a manual now for our operator of all the different brands.

“What does not help is we encounter EV-drivers who don’t know where the neutral is in their car, because they have not used it before. Some EV cars, like Tesla, have a special “car wash mode”.

“Much of the work of our operators is to tell the customers what to do. That’s the main reason why I wanted a double belt conveyor and not a single one Because when the car is on the belt nothing will happen, even if the car automatically goes to park mode or switches on the brakes.”

How strict are Norwegian environmental laws, compared to other countries and how does this affect your business?

“We have installed a water treatment installation from Istobal, which recycles approx 80% of the water. This is very rare in Norway because it takes many years to earn the costs.

“In Norway it is not mandatory to use recycled water like it is in some countries. Mainly because we usually have a lot of clean water from the mountains. And it often rains here. In fact we are using fresh drinking water for everything and we don’t need osmosis to get the cars clean.

“Until now water has been quite cheap compared to other countries. But this year has been the first time we have a real shortage of fresh water. Because of climate change and the risen electricity prices in Europe, Norway is now draining their water supplies to produce more electric power. So I presume that the price will soon rise and there will be laws in the future for water treatment.

“The same goes for electricity. It has been quite cheap until now because we had plenty of supply. But I took the precaution to install a complicated system for heating for the cold winters ahead of us. We are using big heating pumps from air to water, and have large tanks with 5000liters of accumulated water and 2000 liters of accumulated glycol. The system is heated at maximum capacity when the price is cheap, usually at night. Then, when the price is higher we can make use of the accumulated heat without adding electricity. The heating is used both for heating the air inside our buildings, water consumption in the car wash and to melt ice and snow on the entrance and exit outside.”

One last question: What are the future plans for Pitlane?

“The main goal is to build up this site to be one of the largest in Norway, and to have a complete energy station that caters to every need of car owners. And if the concept is a success, we will see if there are possibilities to expand to other cities.”

Also read: